Junkosha Launches Thin Wall Etched PTFE Liner in Answer to Customer Demands

Developed to enable complex catheter designs, Junkosha’s new 0.00075-Inch Etched PTFE Liner debuts at MD&M Midwest; also offers customized solutions to meet customers’ unmet needs

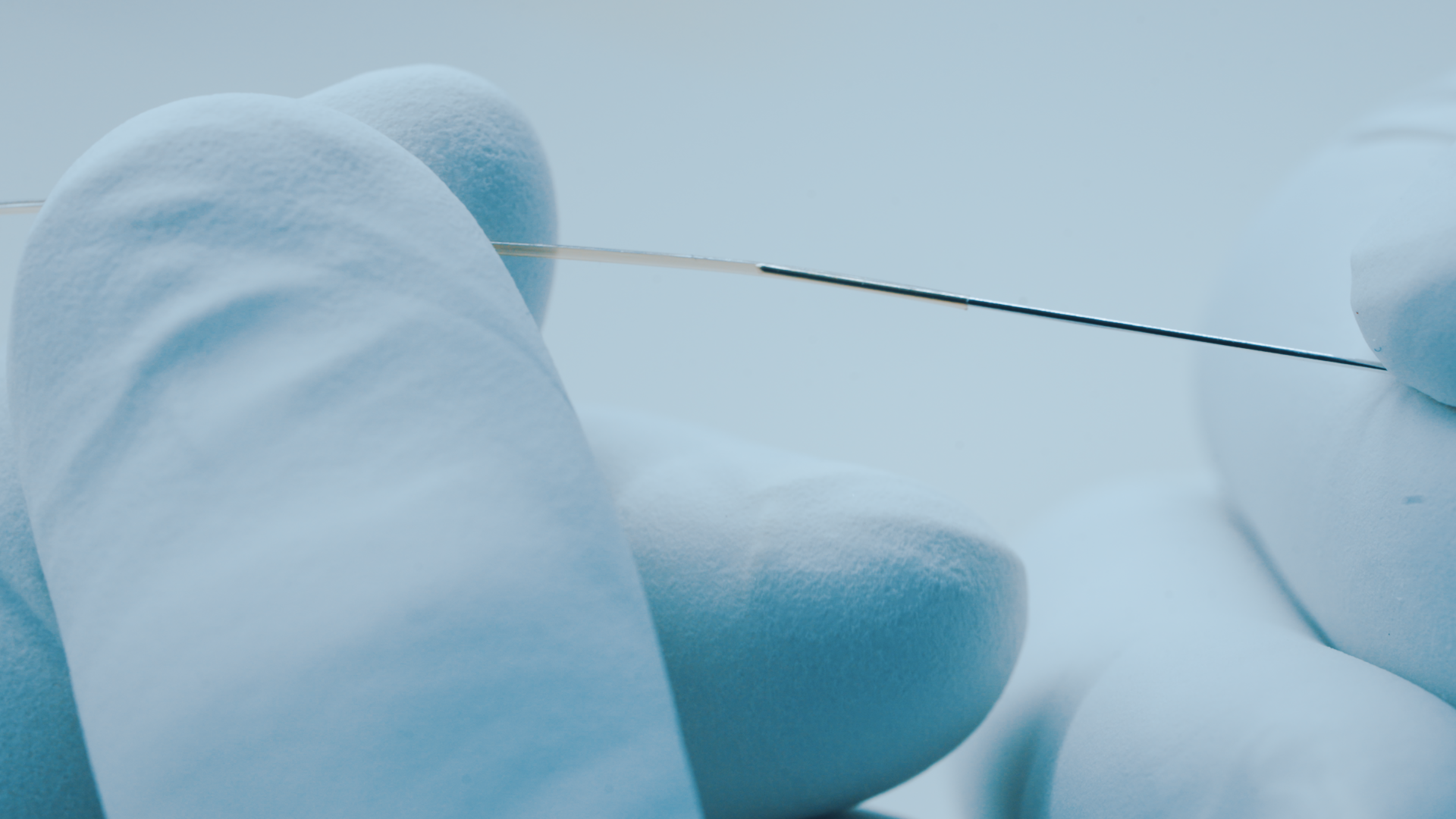

October 20th, 2025 - Junkosha, a pioneer in advanced fluoropolymer technologies, has chosen this year’s MD&M Midwest event to announce a significant advancement in its medical tubing portfolio; the launch of its Thin Wall Etched PTFE Liner range with wall thicknesses as thin as 0.00075 inches (19 µm). This new variant of the Etched PTFE Liner supports a wide range of catheter inner diameters, making it suitable for a wide range of applications including neurovascular and coronary as well as peripheral and structural heart procedures. This flexibility allows engineers to design low-profile catheters capable of navigating complex and tortuous anatomies with greater ease. As a result, medical device manufacturers can achieve expanded opportunities to develop next-generation catheters optimized for performance and precision.

Junkosha has long provided Etched PTFE liners with a wall thickness of 0.001 inches (25 µm) for neurovascular and cardiovascular applications. This new, thinner liner expands the company’s capabilities, enabling catheter designs with either a larger lumen diameter or a slimmer outer profile, thereby increasing design freedom for multi-lumen catheters and other complex configurations.

“Many of our customers are pushing the limits on reducing the overall size of their devices as well as improving the trackability of their products to treat a wider range of patients; all the while noting that jacket and braid as well as coil thickness are typically standardized parameters,” explains Yohei Washiyama, Product Lead at Junkosha. “As a result, there is growing interest in thinner Etched PTFE Liner configurations to not only optimize inner-lumen space, but also to increase overall performance for the benefit of the end user: the patient.”

“With this reduction in wall thickness, and for the same post-lamination thickness, the 0.00075-inch liner requires less elongation,” continues Washiyama. “This minimizes damage to the surface treatment during elongation and is expected to improve adhesion quality with the jacket resin. The result is enhanced catheter flexibility and performance in navigating narrow and tortuous vessels,” Washiyama concludes.

The new Thin Wall Etched PTFE Liner retains Junkosha’s hallmark combination of high lubricity, consistency in elongation and strong tensile profile, serving as a reliable backbone for advanced catheter systems. It maintains low friction and robust durability even when passing through miniature neurovascular and cardiovascular devices, providing smooth device delivery. In addition, it provides strong adhesion to pebax and other outer jacket materials, resulting in a stable and durable bond throughout catheter assembly.

Junkosha’s patented high-tensile PTFE technology ensures greater process control and product uniformity, enabling manufacturers to achieve reliable, high-performance results even in demanding applications. This process delivers stable tensile strength and precise dimensional control, which together promote uniform wall thickness and dependable product quality both within lot and lot to lot. Additionally, it incorporates consistent etched surface treatments reducing the risk of delamination or other quality issues even in the most intricate catheter designs and demanding processing conditions.

To find out more about Junkosha’s new Thin Wall Etched PTFE Liner, please visit Junkosha’s booth (#3717) at MD&M Midwest.