Designing Better Catheters: The Subtle PTFE Liner Details That Drive Quality

Choosing the Right ID: Mandrel Clearance Matters

Two parameters that often go unnoticed -

• Mandrel clearance

• Post-lamination wall thickness

- can make or break both manufacturability and catheter performance.

During production, mandrels must be inserted into PTFE liners without deformation or insertion failure. To achieve this, engineers should compare the upper tolerance of the mandrel’s outer diameter with the lower tolerance of the liner’s inner diameter. The correct clearance depends on factors such as mandrel rigidity, insertion method, and static conditions. Striking a balance helps maintain smooth insertion and dimensional stability.

Post-Lamination Wall Thickness: Thin, But Not Too Thin

To meet growing demands for smaller, more trackable devices, engineers often push the limits of liner thinness. However, excessive elongation of PTFE can weaken the etched surface, reducing adhesion strength between the liner and the outer jacket resin.

The challenge lies in finding the balance between elongation and adhesion. When setting wall thickness, consider elongation ratios, surface treatment durability, and lamination conditions to achieve consistent yields and performance.

The Role of High Tensile Strength

High tensile strength in PTFE liners enhances mechanical integrity across the entire catheter system. Benefits include:

• Improved deliverability: Extruded PTFE liners exhibit high mechanical strength, providing strong resistance against radial forces exerted by self-expandable devices during passage.

• Better control: Even in catheters exceeding 1.5 meters in length, extruded PTFE liners minimize transmission loss, maintaining efficient force delivery throughout the device.

Consistency in Stretch Tensile Strength

Even with identical lamination conditions, small variations in tensile strength can lead to uneven elongation and dimensional inconsistency. By incorporating stretch tensile strength as a defined parameter alongside lamination temperature, load, and mandrel dimensions, engineers can achieve greater process reproducibility and catheter quality.

Through our patented high-tensile PTFE technology, Junkosha enables customers to define tensile strength as a key specification, giving engineers greater control over process consistency and device performance.

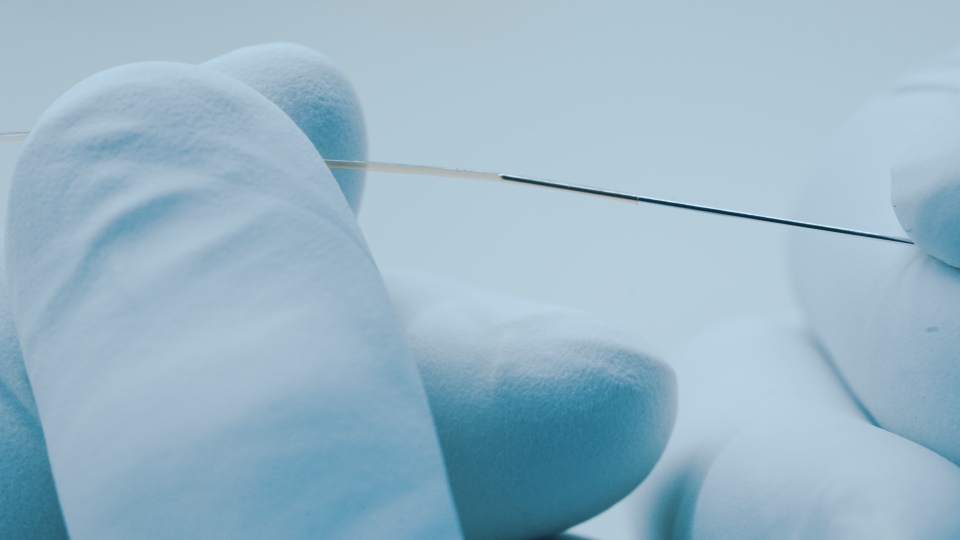

Why Surface Treatment Enables Adhesion

PTFE possesses extremely high non-stick properties, which makes it difficult to bond. Sodium etching (commonly known as Tetra-Etch treatment) addresses this by stripping fluorine atoms to create reactive carbon sites, allowing strong chemical bonds with outer materials.

The brown hue of a treated PTFE liner is more than cosmetic - it’s a visible indicator of successful activation, essential for reliable adhesion during multilayer catheter construction.

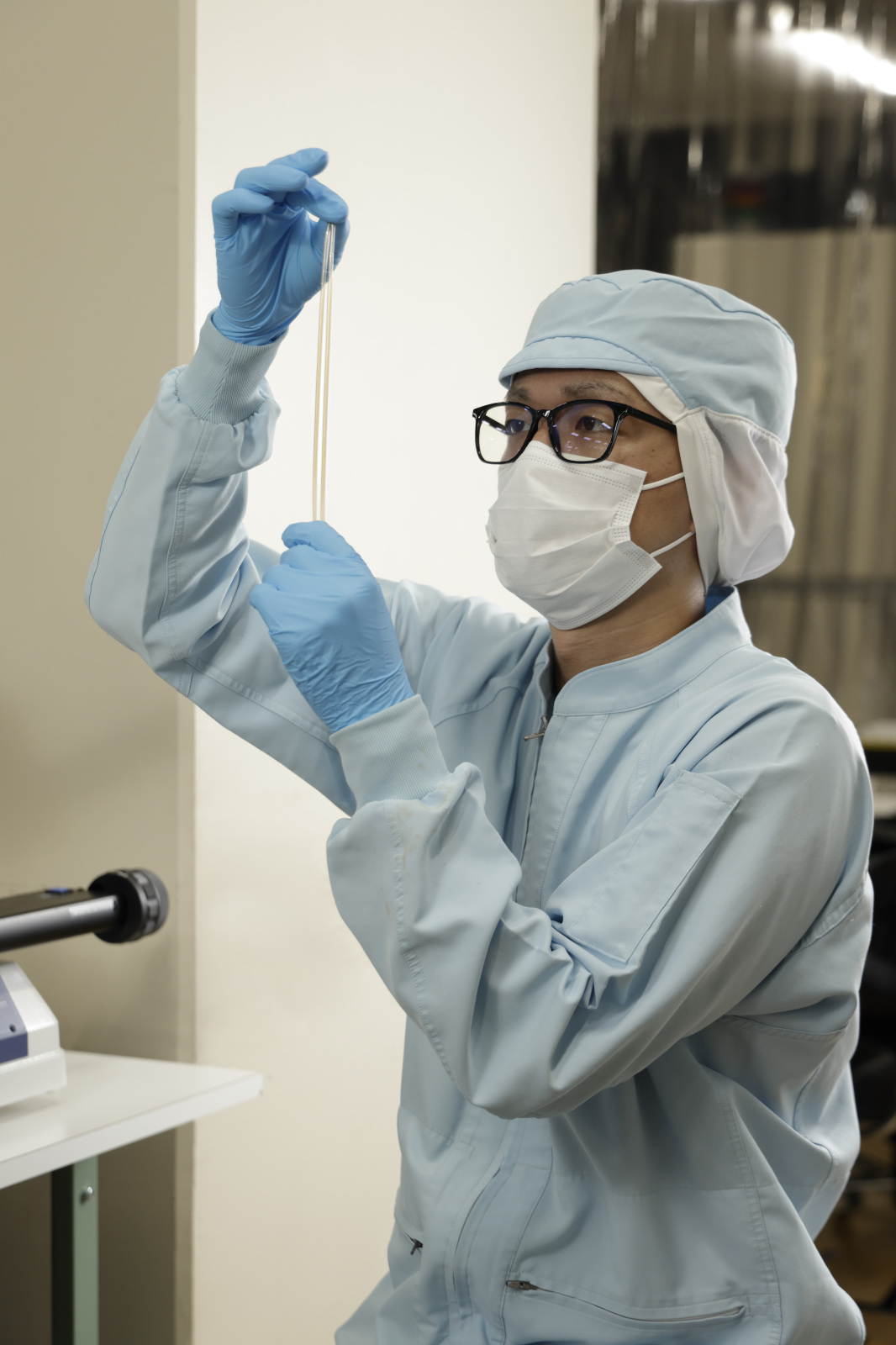

Protecting Etch Quality

Etched PTFE is highly sensitive to UV and mechanical stress. Prolonged light exposure can degrade surface activity.

To safeguard performance, each Junkosha Etched PTFE Liner is processed using automated inspection and sealed in black packaging to maintain consistent bonding characteristics for the duration of the specified period.

Engineering Confidence Through Control

For catheter engineers, achieving consistent performance starts with the control of tolerances, tensile strength, and surface treatment quality. Junkosha’s decades of PTFE processing expertise and proprietary liner technologies enable precisely that, supporting high-yield manufacturing and reliable device performance at scale.

If you’re developing advanced catheter systems, our team can support your liner and lamination design challenges.