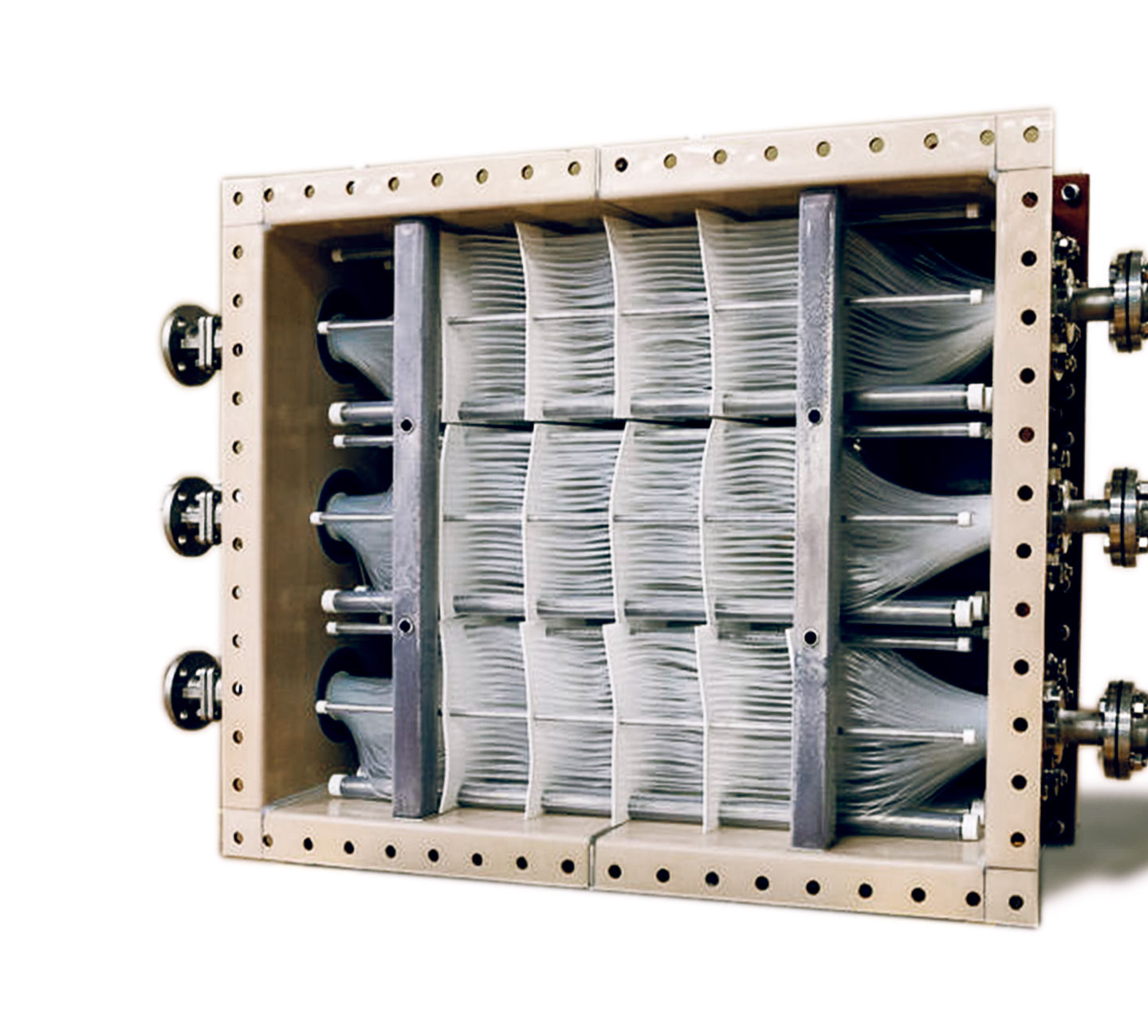

Junkosha Heat Exchanger

The semiconductor field as well as chemical, pharmaceutical, and steel plants require heat exchangers that can be incorporated into various processes and withstand harsh conditions (such as corrosion, temperature, pressure, staining resistance, and durability).

To provide the properties which satisfy the demanding requirements of such a wide range of markets, Junkosha developed high-performance, high-quality, high-durability fluoropolymer heat exchangers based on our wealth of experience and unique processing technology accumulated over many years.

To provide the properties which satisfy the demanding requirements of such a wide range of markets, Junkosha developed high-performance, high-quality, high-durability fluoropolymer heat exchangers based on our wealth of experience and unique processing technology accumulated over many years.

Features

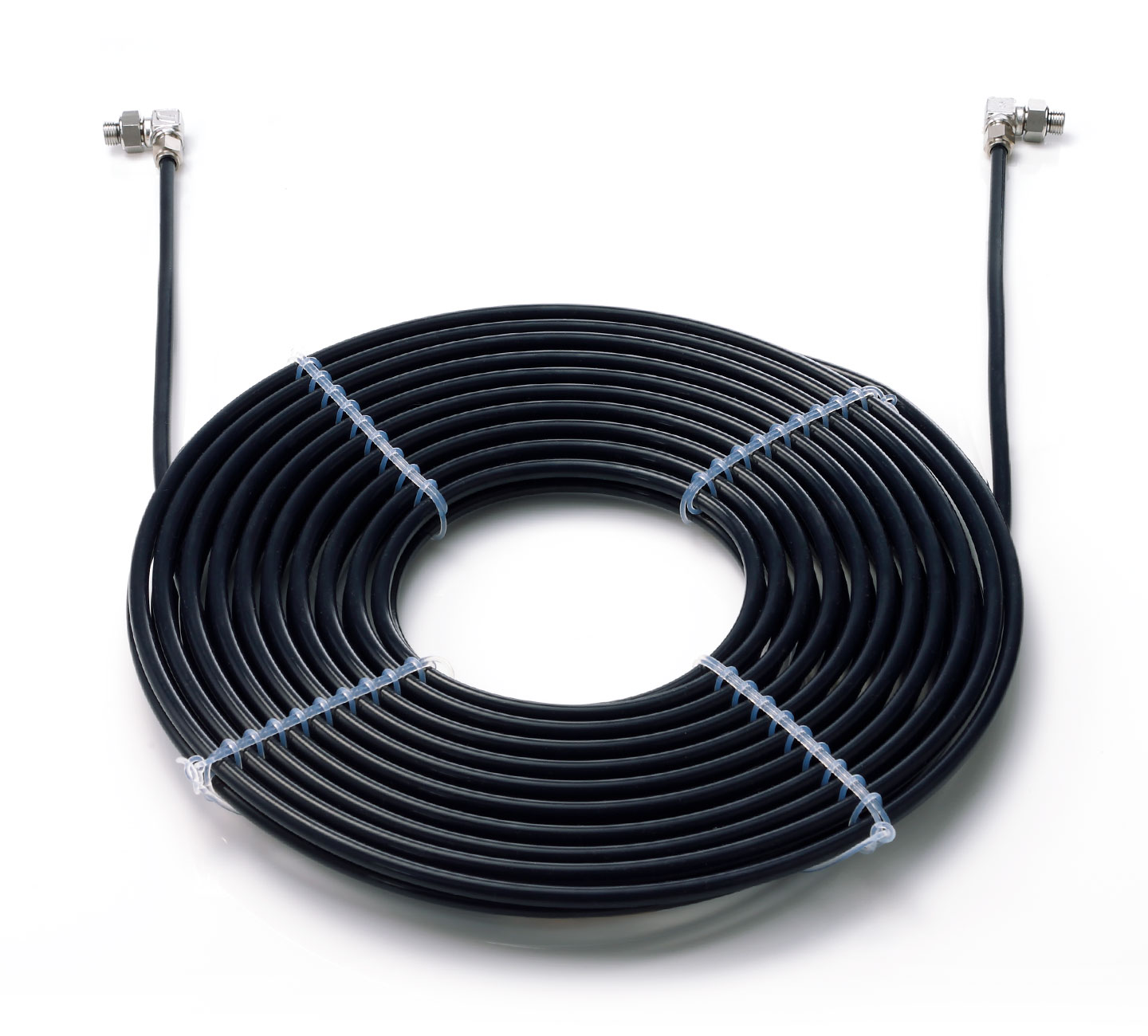

- Fluoropolymer PFA used for heat transfer tubes provides resistance to most chemical agents and solvents.

- Excellent environmental stress cracking resistance and heat durability under high temperature. It is also flexible and will not break due to heat and mechanical shock, which may occur with glass and graphite.

- No dissolution of harmful substances and does not contaminate the processing fluid. The round end surface has a honeycomb structure processed with our unique fusing technology, achieving high strength and also saving space.

- Adhesion resistance means that scales and sludge are unlikely to stick, and even if they do, they can be removed easily.

- Heat transfer area per unit volume is large, suitable for compact installation.

- Compact, lightweight, and easy to handle, so maintenance is also very easy.

- Excellent environmental stress cracking resistance and heat durability under high temperature. It is also flexible and will not break due to heat and mechanical shock, which may occur with glass and graphite.

- No dissolution of harmful substances and does not contaminate the processing fluid. The round end surface has a honeycomb structure processed with our unique fusing technology, achieving high strength and also saving space.

- Adhesion resistance means that scales and sludge are unlikely to stick, and even if they do, they can be removed easily.

- Heat transfer area per unit volume is large, suitable for compact installation.

- Compact, lightweight, and easy to handle, so maintenance is also very easy.

Use

- Chemical plants

| FXS-105 | FXS-450 | FXS-185 | |

| Tube Material | PFA | PFA | PFA |

| Tube Size | 6.4mm×5.2mm | 3.2mm×2.4mm | 3.2mm×2.4mm |

| Number of Tubes | 109 | 451 | 186 |

| Maximum Operating Pressure on Tube Side (Saturated Steam) | 0.29 MPa(143℃) | 0.49 MPa(158℃) | 0.49 MPa(158℃) |

| Shell Side Maximum Operating Pressure (Saturated Steam) | 0.20 MPa(133℃) | 0.20 MPa(133℃) | 0.20 MPa(133℃) |

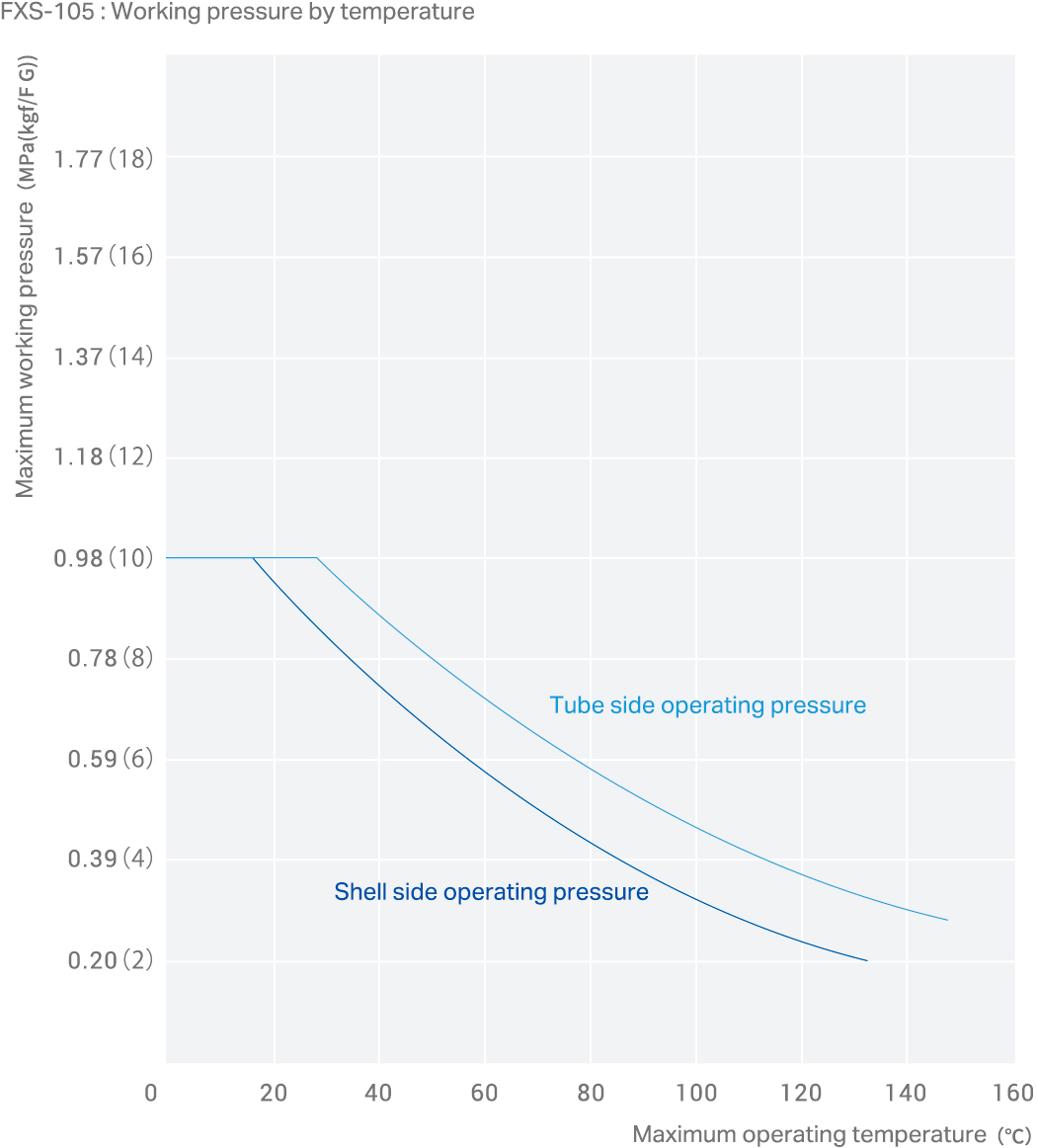

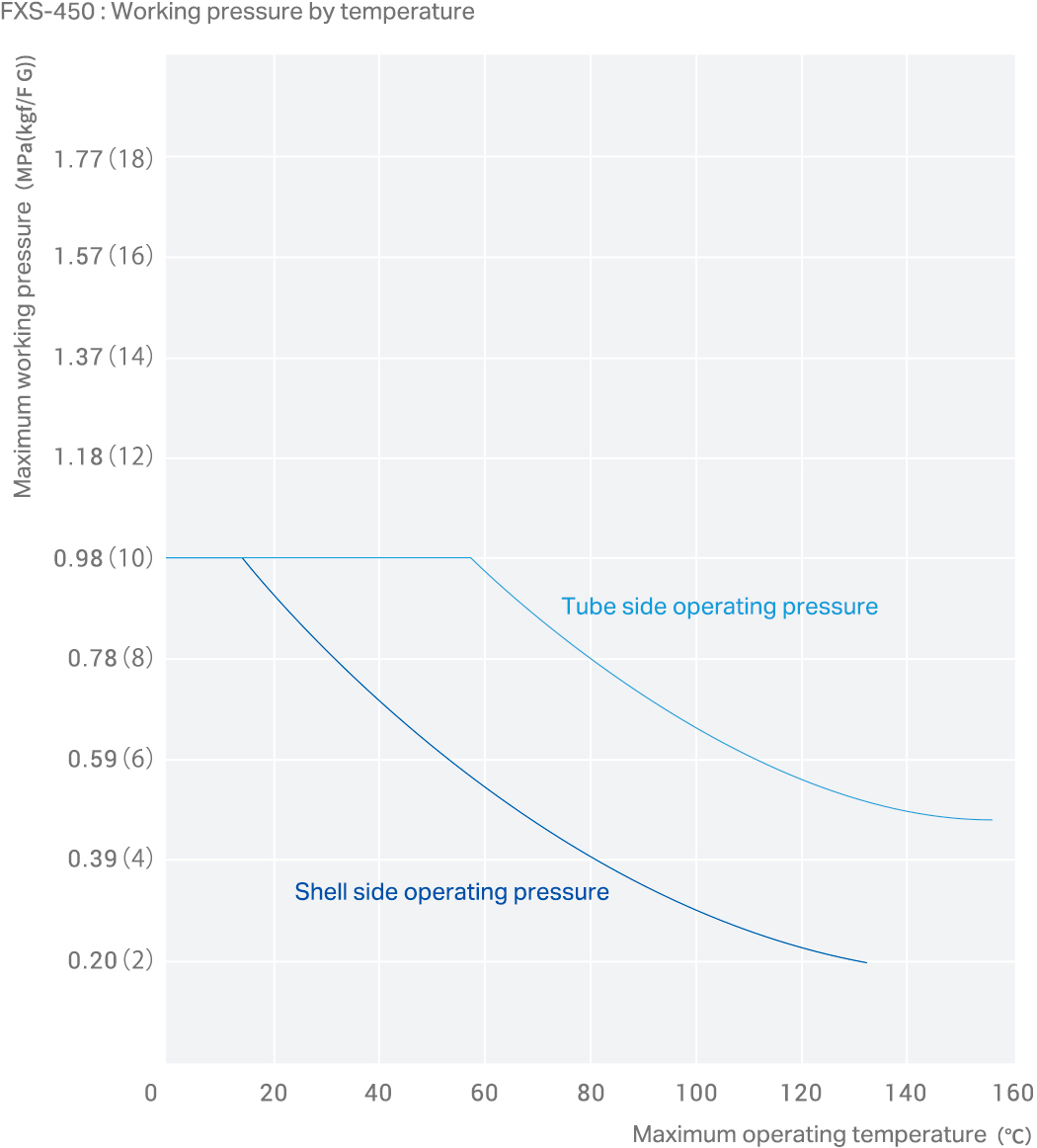

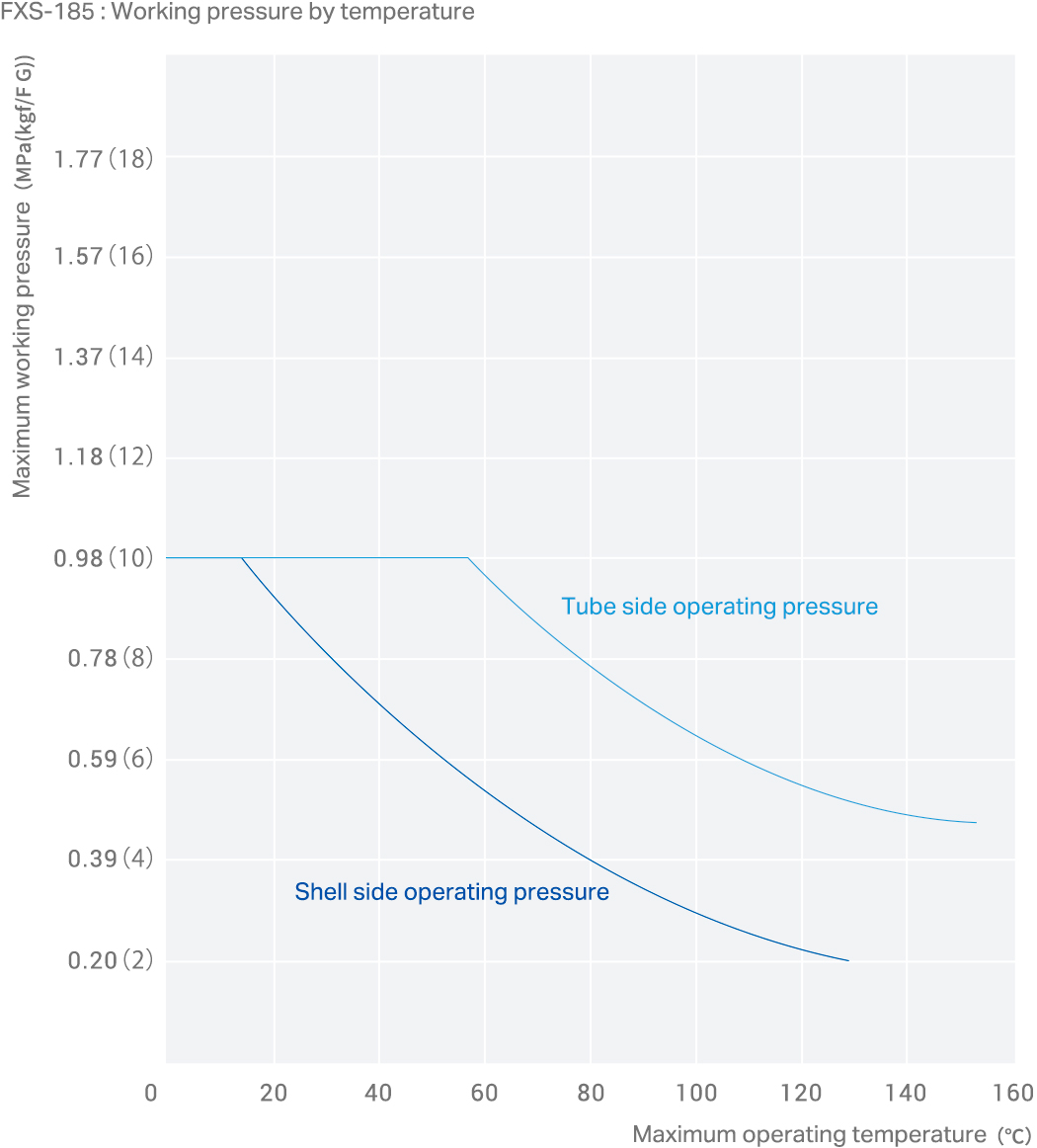

Working Pressure by Temperature

- Search for products that interest you

-