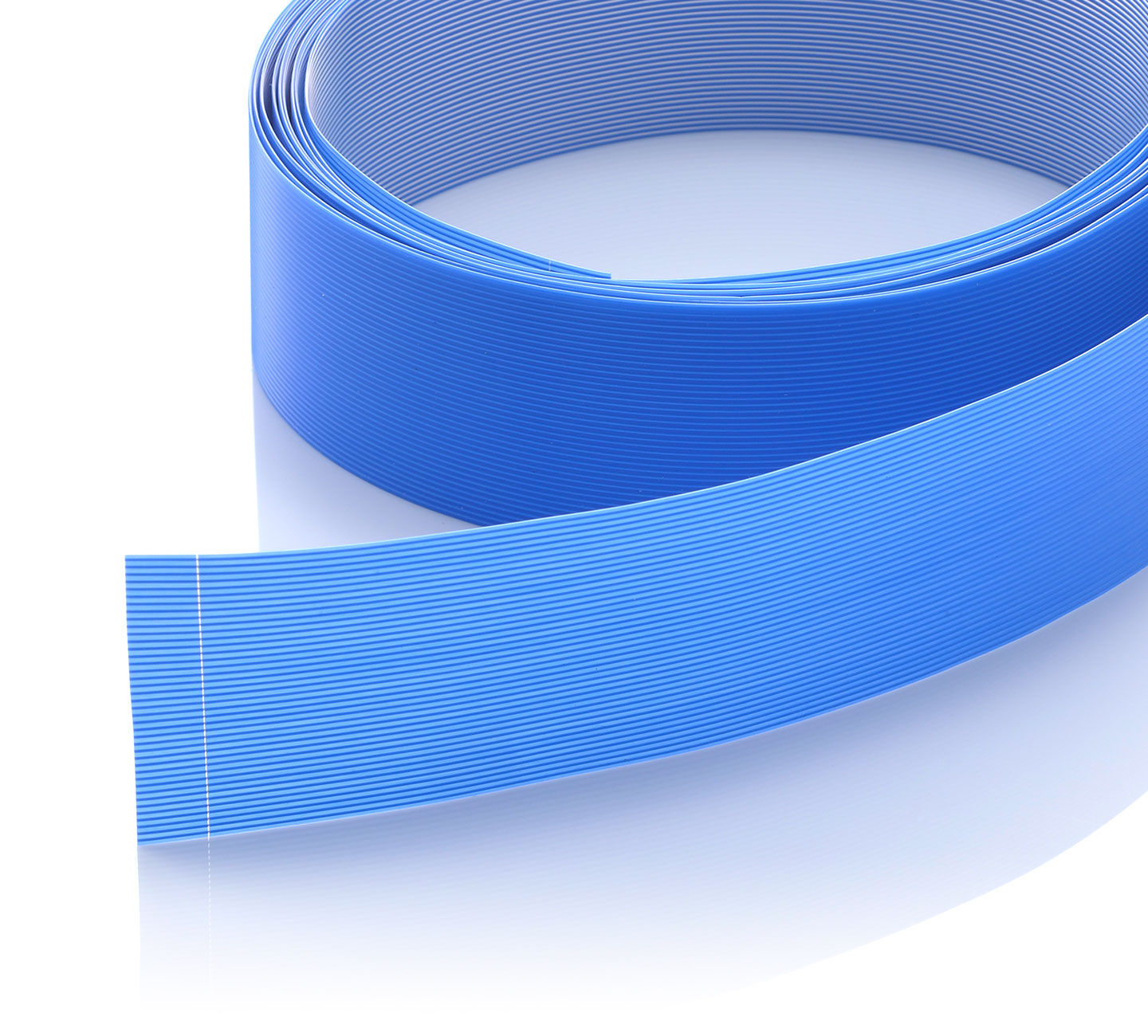

Junkosha Flat and High-Flex Cable

The demand for semiconductors is significantly increasing due to 5G, AI, autonomous driving, cloud services, IoT, EV vehicles, the metaverse, and other developments. Simultaneously, based on Moore's Law, semiconductor lithography is achieving finer line widths, while the precision of the process is advancing. With the advancement of technology, particles and outgassing during the process are becoming a growing issue. To address this, cleaner materials (low particles, low outgassing) are being sought. These materials are crucial to respond to advancements in various technological fields.

Junkosha has been providing clean and highly durable cables that meet these requirements for over 40 years. These cables place particular emphasis on cleanliness (minimizing dust generation due to outgassing and cable wear) and flexibility compared to conventional options. In addition, the use of clean cables is a step towards carbon emission reduction as the amount of time and energy in the outgas chamber is reduced. Junkosha's lineup includes a Low Outgassing (LO) type, suitable for use in environments ranging from atmospheric pressure to medium vacuum, and Super Low Outgassing (SLO) type, suitable for use in environments from high vacuum to ultra-high vacuum.

Junkosha has been providing clean and highly durable cables that meet these requirements for over 40 years. These cables place particular emphasis on cleanliness (minimizing dust generation due to outgassing and cable wear) and flexibility compared to conventional options. In addition, the use of clean cables is a step towards carbon emission reduction as the amount of time and energy in the outgas chamber is reduced. Junkosha's lineup includes a Low Outgassing (LO) type, suitable for use in environments ranging from atmospheric pressure to medium vacuum, and Super Low Outgassing (SLO) type, suitable for use in environments from high vacuum to ultra-high vacuum.

Features

- Low Outgassing: Minimal outgassing, especially compared to other materials

- Flexibility: Flexibility, a drawback of fluoropolymers, greatly improved

- High Durability: Proposals in accordance with the customer's life expectancy for moving parts

- Low Friction: Compared to other materials, low friction is dramatically improved

- Flexibility: Flexibility, a drawback of fluoropolymers, greatly improved

- High Durability: Proposals in accordance with the customer's life expectancy for moving parts

- Low Friction: Compared to other materials, low friction is dramatically improved

Use

- Various high-precision machines including semiconductor and FPD manufacturing equipment

- Satellites and other space equipment

- Satellites and other space equipment

- Search for products that interest you

-